WHAT IS VOLUMETRIC CONCRETE AND HOW DOES IT WORK?

In short, Volumetric Concrete Production is an advanced production technology designed for precision, flexibility, waste reduction, and yielding a fresher, quality product.

Volumetric concrete, a construction innovation, involves the on-site production through volume-based material dispensing and mixing, instead of conventional material weight batching and mixing. Utilizing specialized volumetric concrete mixers (VMs), this approach offers continuous batch precision and control in producing always fresh concrete only when required and yielding exact quantities only as needed, thereby eliminating concrete waste.

VMs are essentially truck-mounted concrete batch plants equipped with dispensing bins for raw materials like cement, aggregates, water, admixtures, and additives. Utilizing the VMs Material Control System, the flow of all mix components are accurately coordinated, metered, and monitored onto a conveyor belt and into a mixing bowl. This ensures precise dispensing of mix proportions, conforming to prescribed mix designs and yielding accurate concrete quantities with consistent quality results. Mixing occurs in the auger, synchronized with conveyor belts and material flow rates to ensure thorough, high-energy, high-sheer agitation. The final mixed concrete is dispensed onto chutes and poured on site where desired.

In addition to preserving concrete quality through accurate, fresh batching and eliminating concrete waste, VMs further offer the advantage of mix design flexibility. Multiple mix designs can be used from the same truck and mixes can be altered to suit the customers’ changing slump and air requirement project needs.

GET A CONCRETE QUOTE FOR YOUR PROJECT?

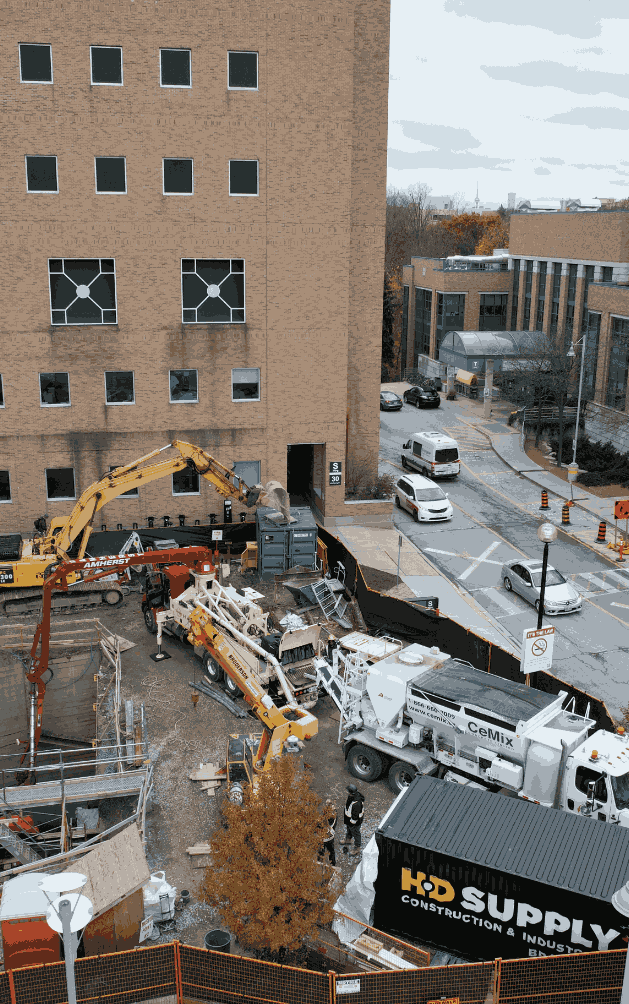

Experience the difference and switch to volumetric concrete for your next job. Contact the CeMix team today and receive a FREE quote!

TESTIMONIALS